Compounds incl. HP-T proprietary compounds

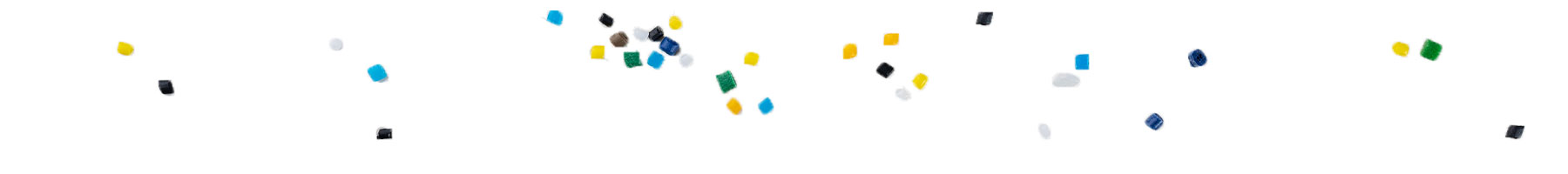

So-called additives can be used in the extrusion process to match the properties of virgin material. The addition of these additives results in a so-called plastic compound.

HP-T develops polymer materials with individual mechanical, thermal and chemical properties for its customers (e.g. in the automotive, medical and communications technology sectors).

We offer these in various batch sizes.

Our strength is the use of different fillers, whether glass/carbon fibers, talc or additives of various kinds, whereby we orient ourselves precisely to the specifications of our customers.

HP-T own compounds

All product names are registered trademarks and some have been established on the market for more than 10 years. Depending on customer requirements, our compounds can be manufactured on the basis of virgin material recyclate. Our own products can be modified according to customer requirements or specifications.

You can find the corresponding CO₂ balances for our products here.

The Hoegolen series stands for all polyolefin (PE and PP) based compounds. As examples:

- Hoegolen® AIM GF10 blue 5117 antioxidation and impact modified for technical automotive parts (HD-PE glass fiber reinforced)

- Hoegolen® PP J20 E black Injection molding grade for increased requirements (PP/elastomer modified)

The Hoegerin series stands for all polyoxymethylene (POM or also known as polyacetals) based compounds. For example:

- Hoegerin® 511 L POM homopolymer – suitable for common injection molding applications available both on the basis of virgin material and recycled material

- Hoegolup® AIM PE-HD – suitable for injection molding and extrusion applications (e.g. automotive tank area)

The Hoegoblend series stands for all polymer blend-based compounds such as PC/ABS

We can offer a wide range of products, from lower-priced compounds for “non-visible” applications, to high-end qualities for the automotive interior sector, for example.

The Hoegomid series includes PA6, PA66 and copolyamide PA66/6 compounds Our specialty here is the optimization of mechanical strength and increased processability. Through further modification, flame retardancy of class UL94 V0 at 0.8 mm can also be achieved. Our Hoegomid® 66 GF25 FRV0 (PA 6.6 GF25 V0), which is suitable for all electronics applications (for example in the home or motor/commercial vehicle sector), meets the requirements of UL 94 V0.

With the Hoego®-PET series, we are pursuing a completely new approach – 100% PET recyclate, 0% from the bottle cycle and 100% upcycling. A versatile material, particularly suitable for injection molding, injection blow molding and extrusion, which also has an extremely low CO2 footprint. The material’s inherent silver color creates opportunities for extremely high-quality visual applications and offers a significant price advantage compared to coloring during the subsequent manufacturing process. In addition to the silver color, Hoego® PET is also available in black An excerpt of possible areas of application for our Hoego®-PET:

- Cosmetics packaging (e.g. eyeliner, mascara, shampoo)

- Care product packaging (e.g. car care, furniture care, household cleaners)

- Decorative elements / trims

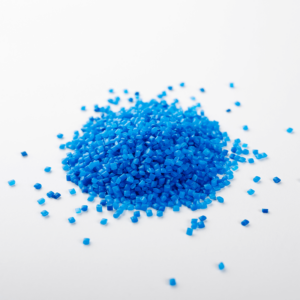

Hoego®Wash(rim cleaning granulate) Hoego®Wash products are granules specially designed for rim cleaning. They ensure gentle and at the same time thorough rim cleaning. (Only suitable for cleaning systems) Hoegoprotekt® (stone layer protection) With the Hoegoprotekt® series , we have developed a time-saving and cost-reducing layer protection for your concrete or natural stone products. No more scratches caused by transportation and storage on high-quality stone products and 100% recycled material.

Do you have questions about a product? We will be happy to help you.

You have not yet found the right product for your application? Contact our research and development department!

We will work with you to develop the right product for your application.